In the world of electronics, circuit board repair is an invaluable skill for both hobbyists and professionals. Printed circuit boards (PCBs) are integral to nearly every electronic device, from appliances to sophisticated machinery.

However, circuit boards are prone to damage due to factors like poor design, physical damage, power surges, and wear and tear. Understanding how to repair these delicate components can save you money and extend the life of your devices.

This guide will help you navigate the circuit board repair process, from diagnosing problems to fixing copper traces and finding circuit board repair services near you.

Whether you’re a novice looking to learn circuit board repair training or a professional seeking advanced techniques like BGA rework, we have you covered.

Common Causes for Circuit Board Damage

Printed Circuit Boards (PCBs) are essential to the functionality of almost every electronic device. However, they are vulnerable to failure due to various factors that can impact their performance.

Whether you’re working on automotive electronics, appliance circuit boards, or instrument clusters, understanding the common causes of PCB failures is crucial for effective repair and prevention. Here are the most frequent causes of PCB failures and how they occur:

1. Physical Damage

Physical damage is one of the most common causes of PCB failure. PCBs are often subjected to mechanical stress, and even minor impacts can cause significant issues:

- Cracks and Fractures: Physical impacts or stress can result in cracks or fractures, which can disrupt the circuit paths and cause open circuits.

- Bending: If a PCB is bent beyond its limits, it can cause traces or pads to lift off, creating an open circuit.

- Broken Components: The physical handling of components can lead to broken pins, leads, or pads which can severely impact performance.

2. Overheating

Excessive heat is a leading cause of PCB damage. Components on the PCB generate heat during operation, and if the board isn’t designed for proper heat dissipation, this can lead to:

- Thermal Stress: Components like resistors, capacitors, and ICs can fail due to excessive heat. The PCB traces can also deteriorate when exposed to high temperatures.

- Solder Joint Failure: Solder joints may crack or weaken under thermal cycling, which can lead to poor connections or complete circuit failure.

3. Power Surges

Power surges, whether caused by voltage spikes, static discharge, or lightning strikes, can cause PCB failures in an instant. Power surges can cause:

- Burnt Components: Sensitive components, such as capacitors, diodes, or microchips, are vulnerable to sudden voltage changes. A surge can burn out components, rendering the PCB inoperable.

- Damaged Traces: High voltage spikes can also damage the copper traces or pads on the PCB, causing short circuits or open circuits.

4. Corrosion

Exposure to moisture, humidity, or chemicals can lead to corrosion on the PCB. This affects both the copper traces and the solder joints. Corrosion can cause:

- Weakened Electrical Connections: Corroded traces can increase resistance, causing poor connectivity and malfunctioning circuits.

- Component Damage: Moisture can seep into component leads, leading to oxidation or corrosion of sensitive parts such as diodes or transistors.

5. Soldering Issues

Soldering problems are a frequent cause of PCB failure, especially if the process is rushed or done improperly. Common soldering issues include:

- Cold Solder Joints: Poorly made solder joints result in weak connections, which may cause intermittent faults or completely prevent current flow.

- Solder Bridges: Excess solder can connect adjacent pads, leading to short circuits or unintended connections.

- Excessive Heat During Soldering: Applying too much heat to a component can damage it or affect the surrounding PCB traces.

Proper soldering techniques are crucial to avoid these problems and ensure reliable connections on the PCB.

6. Poor Design

Design flaws in the PCB layout can lead to failures during the circuit board operation. Some common design-related failures include:

- Improper Trace Width: If the trace width is too narrow for the amount of current it needs to carry, it can overheat and cause failure.

- Inadequate Grounding or Power Distribution: Insufficient ground planes or poorly routed power traces can result in poor signal quality, noise, or even component damage.

- Component Placement Issues: Incorrect placement of components can lead to signal interference, poor thermal dissipation, or electromagnetic interference (EMI).

Ensuring that the PCB design is well-planned and optimized for both functionality and manufacturability is critical in preventing these types of issues.

7. Electrostatic Discharge (ESD)

Electrostatic discharge (ESD) is a sudden flow of electricity between two objects with different electric potentials, which can severely damage electronic components. Sensitive components such as microchips, diodes, and ICs are vulnerable to ESD damage. Static discharge can:

- Fry components: Even a small amount of static can destroy sensitive parts, leading to total failure.

- Damaged Solder Joints: ESD can also break solder joints, resulting in faulty connections.

Proper ESD protection measures, such as antistatic bags, grounding mats, and ESD-safe tools, are essential to prevent static damage.

8. Vibration and Mechanical Stress

Vibration and mechanical stress can cause damage to PCBs over time, especially in high-demand environments like automotive electronics or industrial machinery. These issues can cause:

- Component Loosening: Vibration may cause components or connectors to loosen or detach from the PCB, disrupting the functionality.

- Cracking of PCB Substrate: Continuous vibration may cause small cracks in the PCB substrate, affecting signal integrity or causing complete failure of the board.

To prevent mechanical stress damage, ensure proper mounting, shock-proof enclosures, and vibration-resistant components.

9. Component Failure

In some cases, a component failure leads to an overall PCB failure. The components on the board are susceptible to wear and tear over time, especially under harsh operating conditions. Common component failures include:

- Capacitor Degradation: Capacitors can wear out over time, leading to reduced capacitance, leakage, or complete failure.

- Resistor Burnout: Excessive heat or overcurrent conditions can burn out resistors, affecting the board’s performance.

- IC Failure: Integrated Circuits (ICs) may fail due to overheating, poor power supply, or manufacturing defects.

Regular maintenance, component testing, and proactive replacement can help mitigate these types of failures.

10. Poor Manufacturing Quality

Sometimes, PCBs fail due to poor manufacturing quality. This can be caused by:

- Incorrect Component Specifications: Using components that don’t meet the required voltage, current, or power specifications can lead to failures.

- Manufacturing Defects: Faulty soldering, poor component placement, or errors during the PCB fabrication process can cause malfunctioning boards.

- Quality Control Issues: If proper testing and inspection are not performed, defective PCBs may be sent out for assembly, leading to failures in the field.

Working with reputable electronics manufacturers who prioritize quality control can minimize this risk.

To avoid the issues mentioned above, selecting a trustworthy PCB manufacturer is essential. A good manufacturer should have the following characteristics:

- Strict Quality Control System: Ensures that every production step undergoes rigorous quality checks.

- Advanced Production Equipment and Technology: Uses modern equipment and techniques to ensure PCB accuracy and reliability.

- Experienced Team: Employs skilled engineers and technicians who can address various manufacturing issues.

- Good Customer Reputation: Assess the manufacturer’s reputation and service quality through customer reviews.

What Does the Most Damage to Circuit Boards?

Even the best-designed printed circuit boards are most vulnerable to two primary threats: excessive heat and electrical overstress. These stressors attack the board’s copper traces, solder joints, and components at rates far faster than physical wear or corrosion.

Addressing thermal management and surge protection directly mitigates the causes of the vast majority of PCB failures.

| Cause | Why It’s So Damaging | Key Effects | Prevention |

| Thermal Stress(Overheating) | Heat accumulates when high-power components lack sufficient dissipation. Prolonged exposure strains solder joints and substrate materials. | – Cracked or delaminated copper traces- Brittle or “dry” solder joints- Component degradation (e.g., electrolytic capacitors bursting) | – Design in heat sinks, thermal vias, copper pours- Ensure adequate airflow or forced cooling |

| Electrical Overstress(Power Surges & Spikes) | Sudden voltage/current spikes exceed component and trace ratings, causing instantaneous damage before protective elements can react. | – Instant burnout of semiconductors (diodes, MOSFETs, ICs)- Melted or vaporized copper traces- Localized substrate carbonization | – Add TVS diodes, MOVs, fast-blow fuses on power inputs- Implement upstream voltage regulation |

How to Repair a Printed Circuit Board (Step-by-Step)

Repairing a Printed Circuit Board (PCB) involves diagnosing and fixing faults in the circuitry, components, and traces. Whether it’s a burnt PCB, damaged traces, or a faulty component, PCB repair can often restore functionality and extend the life of the board. This guide will walk you through the process of repairing a PCB, from diagnosing issues to replacing components and fixing damaged traces.

Step 1: Diagnose the Problem

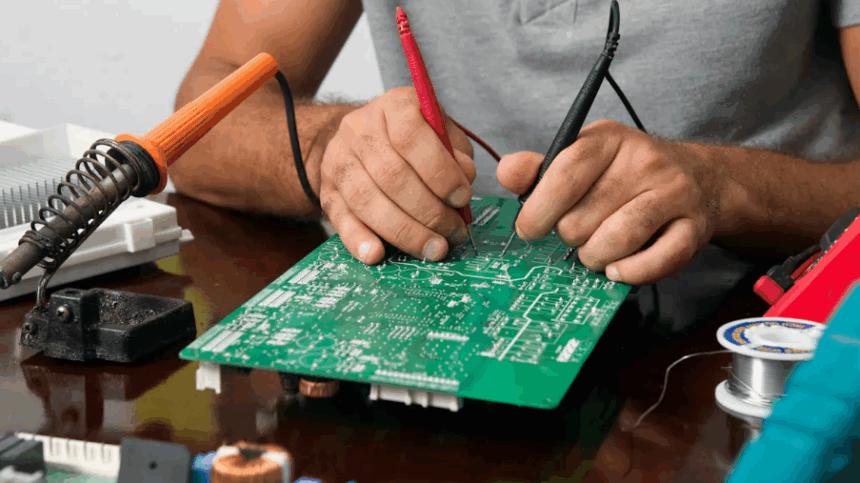

The first step in PCB repair is to understand what’s wrong. Start by looking closely at the circuit board. Search for damage like burnt spots, broken lines, or loose parts. Use a magnifying glass to see tiny cracks or faded areas that are hard to notice.

Look at the solder joints carefully. Bad soldering can cause weak links, stopping the board from working. Check for dirt, rust, or leftover materials on the board. These can block electricity and must be cleaned before fixing anything.

A. Visual Inspection

- Check for obvious damage. Look for burnt components, cracked PCB, damaged copper traces, or broken pads. Damaged areas will often show signs of discoloration, burn marks, or cracks.

- Corrosion: Look for signs of rust or corrosion around component leads, solder joints, and vias, especially if the PCB has been exposed to moisture.

- Loose components: Inspect whether any components are detached or loose.

B. Use a Multimeter

- Continuity Testing: A multimeter is essential for checking continuity. You can test if the circuit traces are intact and identify if any traces are open (broken) or shorted (connected improperly).

- Component Testing: Test individual components like resistors, capacitors, and diodes to see if they are working correctly or if they need replacement.

C. Identify Faulty Components

- Burnt Components: Common components that often burn out include capacitors, resistors, and diodes. If a component looks burnt or damaged, it likely needs to be replaced.

- Solder Joint Issues: If there are cold solder joints or solder bridges (unwanted solder connecting adjacent pads), they may need to be repaired.

After checking the board, figure out what’s wrong. Use a multimeter to test the board’s parts and paths. This tool measures voltage, resistance, and current to help locate faults.

Step 2: Gather Necessary Tools and Components

To successfully repair a PCB, you’ll need the right tools and components:

Tools for PCB Repairing

| Tool | Description |

| Soldering Iron | A high-quality soldering iron with a fine tip for precision work. |

| Desoldering Pump or Braid | To remove old solder when replacing components. |

| Multimeter | For testing continuity and components. |

| PCB Repair Kit | Includes soldering tools, conductive ink (for repairing traces), flux, and PCB cleaning brush. |

| Hot Air Rework Station | If dealing with complex components like BGA (Ball Grid Array), a hot air station may be needed. |

| ESD-Safe Mat and Wrist Strap | To prevent Electrostatic Discharge (ESD) from damaging sensitive components. |

| Soldering Wire | Use high-quality lead-free solder to ensure clean, reliable joints. |

Components

| Component | Description |

| Replacement Components | May include capacitors, resistors, transistors, or integrated circuits (ICs). |

| Conductive Ink or Copper Foil | For repairing damaged traces. |

| Solder | Lead-free solder is recommended, but traditional tin-lead solder is still used in some cases. |

Step 3: Take Out Broken Parts

Once you know which part is broken, remove it carefully. Heat the solder holding the part with a soldering iron. When the solder melts, use a desoldering pump or wick to clean it off. This clears the area for a new part.

Be gentle to avoid harming nearby parts or lines. If the part is stuck, add a little flux to make heating easier and smoother.

- Warning: Don’t heat the board too much. Too much heat can ruin the board and nearby parts.

- Tip: For small surface parts, use a hot air rework station. It heats the area evenly, making it easier to remove the part without damage. Label the removed parts if you plan to reuse them. This avoids mix-ups when putting everything back together.

Step 4: Repair Damaged Traces

If a PCB trace is damaged or broken, it’s essential to repair it for the PCB to work properly.

A. Use Conductive Ink

- If the damage is minor, conductive ink can be applied to rebuild the circuit trace. You’ll need to clean the damaged area with isopropyl alcohol and a soft brush before applying the ink.

B. Solder a Wire for Larger Breaks

- For more severe trace damage, you can solder a wire across the broken trace. This will act as a replacement electrical path.

- Ensure that the wire is soldered securely to avoid future issues.

C. Copper Foil

- For larger sections of damaged traces, copper foil can be used to restore continuity. Apply the foil and then solder the ends securely. Use a multimeter to check the connection for continuity.

Step 5: Replace Damaged Components

Once you know which part is broken, remove it carefully. Heat the solder holding the part with a soldering iron. When the solder melts, use a desoldering pump or wick to clean it off. This clears the area for a new part.

A. Desolder the Faulty Component

- Desoldering Pump: Use a desoldering pump to remove the solder from the faulty component.

- Desoldering Braid: Alternatively, desoldering braid can be used to soak up the old solder.

B. Prepare the New Component

- Verify the Component: Ensure the replacement component matches the value and specifications of the original.

- Solder the New Component: Place the new component into the PCB pads and solder it into place. Make sure the joints are clean and shiny to ensure proper electrical contact.

C. Test the New Component

- After soldering, test the replacement component with a multimeter to confirm it’s working as expected.

Warning: Don’t heat the board too much. Too much heat can ruin the board and nearby parts.

Tip: Label the removed parts if you plan to reuse them. This avoids mix-ups when putting everything back together.

For small surface parts, use a hot air rework station. It heats the area evenly, making it easier to remove the part without damage.

Step 6: Clean the PCB

Cleaning the board is an important part of fixing it. Dirt and grease can block connections and make repairs fail. You must clean the board before continuing.

- Get Cleaning Supplies: Use 99% isopropyl alcohol, a soft brush, and lint-free cloths. These are safe for electronics and leave no residue. Don’t use water or household cleaners—they can harm the board.

- Use Isopropyl Alcohol: Pour a little alcohol on the brush. Gently scrub the board, focusing on dirty spots. Pay close attention to solder joints and damaged areas.

- Wipe and Dry: Wipe off dirt with a lint-free cloth. Let the board air dry fully. If you’re in a rush, use compressed air to dry it faster.

Tip: Clean in a room with good airflow. Alcohol fumes can be strong, so ventilation keeps you safe. Cleaning removes dirt and makes fixing pads and parts easier.

Step 7: Fix Damaged Circuit Board Pads

Broken pads can stop electricity from flowing, causing problems. Fixing pads takes care, but it’s not too hard if done right.

- Check the Damage: Look closely at the pads to see what’s wrong. Use a magnifying glass to spot lifted, burnt, or missing pads.

- Clean the Area: Wipe the damaged spot with isopropyl alcohol. This clears debris and prepares the surface for repair.

- Fix the Pad: If the pad is loose but still there, glue it back down. For missing pads, use copper tape to replace them. Cut a piece slightly bigger than the damaged area, stick it on, and press firmly.

- Solder the Pad: Solder the pad to the board to secure it. Be careful not to overheat the area, as too much heat can cause more damage.

Note: Practice on an old board if you’re unsure. This helps you learn without risking mistakes.

Fixing pads and traces is a key skill for repairing boards. With practice, you’ll get better and make your devices last longer.

Step 8: Fix Soldering Issues

A. Cold Solder Joints

- Cold solder joints occur when the solder doesn’t melt properly, leading to weak electrical connections. To fix a cold joint:

- Reheat the solder with the soldering iron until it melts properly.

- Add a small amount of fresh solder to ensure a solid connection.

B. Solder Bridges

- Solder bridges occur when excess solder connects adjacent pads. To fix a solder bridge:

- Use a desoldering pump to remove the excess solder

- Carefully re-solder the pads with the correct amount of solder.

C. Reflowing Solder Joints

- For BGA or SMD components, reflow soldering can be used. This technique involves heating the PCB in a controlled way to melt the solder and ensure proper connections without overheating the components.

Step 9: Test the PCB

Before reassembling the device, you need to test the PCB to ensure that the repairs were successful:

- Power the Circuit: Carefully power up the repaired PCB.

- Functional Testing: Check the functionality of the PCB by testing the relevant circuit paths or components.

- Multimeter Check: Use a multimeter to check for continuity, voltage, and proper operation of the circuit.

Step 10: Reassemble the Device

Once you have confirmed that the PCB is functioning properly:

- Reassemble the device by placing the PCB back into its housing and reconnecting all components.

- Test the device as a whole to make sure the repair has fully restored its functionality.

Repairing a printed circuit board (PCB) requires a methodical approach, from diagnosing the problem to executing precise repairs on damaged traces and replacing faulty components. With the right tools, such as a soldering iron, multimeter, and PCB repair kit, even beginners can learn to fix simple issues and extend the lifespan of their devices.

If you need professional help with complex repairs or advanced techniques like BGA rework, consider consulting circuit board repair services to ensure high-quality repairs. For DIY PCB repairs, practice, patience, and proper handling of electronic components are key to mastering the skill.

Tools and Materials for Circuit Board Repair

It’s important to have the right tools for fixing circuit boards. Whether you’re new or experienced, using proper tools makes repairs safer and easier.

Basic Tools for Circuit Board Repair

- Soldering Iron and Solder: A soldering iron is a key tool for fixing boards. It melts solder to connect parts to the board. Pick one with adjustable heat for better control. Use good-quality solder made of tin and lead for strong joints. Lead-free solder is also available and better for the environment.

- Multimeter: A multimeter checks electrical properties like voltage and resistance. It helps find broken parts or short circuits on the board. Digital multimeters are easier to read and more accurate than analog ones.

- Desoldering Pump or Wick: Removing broken parts is important in repairs. A desoldering pump sucks up melted solder quickly. A desoldering wick absorbs solder when heated. Both work well, so pick the one you like best.

Advanced Tools for Complex Repairs

- Hot Air Rework Station: For harder repairs, a hot air rework station is helpful. It blows hot air to heat parts evenly, making them easier to remove or replace. This tool is great for working with small, surface-mounted parts.

- Oscilloscope: An oscilloscope shows electrical signals on the board. It helps find problems like signal issues or strange waveforms. You don’t need it for simple fixes, but it’s useful for tough repairs.

Safety Equipment for Repairing Circuit Boards

- Anti-Static Wrist Strap: Static electricity can harm sensitive parts on a board. An anti-static wrist strap stops this by grounding you while you work. Always wear one to protect your board.

- Safety Glasses: Safety glasses keep your eyes safe from solder splashes or flying bits. They are simple but very important for safety. Always wear them when fixing boards.

With these tools and materials, you can fix many circuit board problems. Start with basic tools and add advanced ones as you get better.

Cleaning and Repair Materials

Using the right cleaning and repair materials is very important. They help circuit boards work well and last longer. Without them, even good repair skills might not work.

Isopropyl Alcohol:

Isopropyl alcohol is great for cleaning circuit boards. It removes dirt, grease, and leftover solder. These can mess up electrical connections.

Use 99% pure isopropyl alcohol to avoid water or other residues. Apply it with a soft brush or lint-free cloth to clean well.

Some devices need more cleaning than others. For example, keyboards may not need much cleaning. But devices like pacemakers must be cleaned carefully to avoid problems. This shows how cleaning materials affect repair success.

| Factor | Description |

| Compliance with specifications | Makes sure cleaning meets standards and reduces defects. |

| Defect rate | Shows how often parts fail due to poor cleaning. |

| Customer return issues | Links cleaning to customer satisfaction and product reliability. |

| Process flexibility | Adapts cleaning methods for different types of devices. |

| Health, safety, and environmental concerns | Considers safety and environmental effects of cleaning materials. |

Using isopropyl alcohol lowers defects and improves repairs. It also stops corrosion caused by leftover residues.

Copper Tape for Damaged Tracks

Copper tape is useful for fixing broken tracks on circuit boards. Tracks are thin copper lines that carry signals. If a track breaks, the circuit won’t work. Copper tape helps fix this without replacing the board.

Cut a piece of copper tape slightly longer than the broken track. Place it over the damaged area and press it down. Solder the ends to make a strong connection. This method is fast and works well for small fixes. Copper tape is also flexible, so it fits complex boards.

Using materials like copper tape keeps circuit boards working. It also saves money by avoiding full replacements.

Tip: Clean the board with isopropyl alcohol before using copper tape. This helps the tape stick better and ensures a strong connection.

By combining isopropyl alcohol for cleaning and copper tape for repairs, you can fix circuit boards like a pro.

10 Expert Tips for Effective Circuit Board Repairs

Repairing circuit boards can be challenging, but with the right techniques, you can improve your skills and achieve better results. Here are ten expert tips to help you navigate the repair process effectively.

Practice Steady Soldering Techniques

Soldering is a key skill for fixing circuit boards. To get better, keep your hands steady and move carefully. Hold the soldering iron like a pen for good control. Avoid shaking or sudden movements while working. Practice on old boards to improve your skills. Aim for smooth, cone-shaped solder joints that hold parts firmly.

Tip: Pick a soldering iron with adjustable heat settings. This helps you control the temperature and avoid damaging the board.

Avoid Overheating Components

Too much heat can harm parts and ruin the board. When soldering, only heat the area for a few seconds. Long heating can burn or bend parts. Use a fine-tip soldering iron to focus on small areas without heating nearby parts.

Watch your tool’s temperature closely. If you see burns or smell something odd, stop and let the board cool. Using flux lowers the solder’s melting point, so you need less heat to fix things.

Warning: Don’t use a soldering iron hotter than the part’s limit. Too much heat can cause lasting damage and make repairs harder.

Use the Right Tools for the Job

Having the right tools makes fixing circuit boards easier. Basic tools like a soldering iron, multimeter, and desoldering pump are must-haves. For harder repairs, tools like a hot air station and oscilloscope are helpful.

Pick tools that fit the size of the parts you’re fixing. Use tweezers for tiny parts and a magnifying glass to see small details. Good-quality tools last longer and work better.

Note: Arrange your tools before starting repairs. This saves time and avoids mistakes from searching for lost items.

Keep Your Workspace Tidy

A tidy workspace makes fixing circuit boards easier and faster. When tools are easy to find, you can focus on repairs. Set up a specific area for your work. Use a strong table with enough room for tools and the circuit board.

Organize your tools neatly. Keep items like the soldering iron, multimeter, and desoldering pump close by. Use small boxes or trays for screws and tiny parts. Label these containers to avoid mixing them up. A magnetic mat can stop small metal parts from rolling away.

Check Connections Before Testing

Always check connections before testing your fixed circuit board. Even one loose wire can cause problems. Look closely at each connection. Use a magnifying glass to find weak solder joints or stray wires that might cause shorts.

Test connections with a multimeter. Place the probes on both ends of a connection. If it beeps, the connection is good. If not, re-solder or fix the broken part. Pay extra attention to areas where you replaced parts. Make sure all leads are firmly attached.

Note: If unsure about a connection, compare it to a working board or diagram.

Write Down Your Repairs

Keeping notes about your repairs can help in the future. Write down the problems, how you fixed them, and the tools you used. These notes make it easier to solve similar issues later and improve your skills.

Use a notebook or app to organize your notes. Include details like the board model, replaced parts, and any challenges. Photos are also helpful. Take pictures before and after repairs for a visual guide.

Replace Components with High-Quality Alternatives

When fixing a circuit board, always pick good-quality parts. Cheap parts might cost less but often break quickly. Using high-quality components makes repairs last longer and work better.

Here’s how to choose the right replacement parts:

- Match Specifications: Check the part’s voltage and resistance. Make sure the new part meets or beats the original’s specs.

- Choose Trusted Brands: Buy parts from well-known companies. These brands make reliable components that follow industry rules.

- Inspect Before Installation: Look for cracks or bent pieces. Even new parts can sometimes be damaged.

Tip: Keep extra good-quality parts in your repair kit. This saves time and ensures you always have dependable replacements.

Using better parts not only fixes the problem but also makes the circuit board last longer.

Use Flux for Cleaner Solder Joints

Flux helps make solder joints strong and neat. It cleans metal surfaces so solder sticks better. Without flux, solder joints can be weak or look messy.

Follow these steps to use flux the right way:

- Apply Flux Before Soldering: Use a small brush to spread flux on the solder pads and part leads.

- Heat the Area: Heat the soldering iron and touch it to the fluxed spot. This gets the area ready for soldering.

- Solder the Joint: Add solder to the heated spot. It should flow smoothly and make a shiny joint.

Note: Clean off leftover flux after soldering. Use rubbing alcohol and a soft cloth to remove any residue.

Flux makes your repairs better and helps the circuit board work properly.

Test Components Individually Before Installation

Testing parts before installing them avoids future problems. A bad part can cause new issues and waste your time. Testing first ensures each part works correctly.

Here’s how to test parts:

- Use a Multimeter: Check the part’s voltage or resistance. For example, test capacitors to see if they hold the right charge.

- Inspect Physical Condition: Look for burns, cracks, or rust. Replace any damaged parts right away.

- Compare with Working Parts: If unsure, compare the part to one you know works.

Warning: Handle parts gently. Static electricity or rough handling can break them before use.

Testing parts saves time and ensures your repair will work well.

Learn from Mistakes and Keep Improving

Making mistakes is normal when fixing circuit boards. Each mistake helps you learn and improve your skills. Don’t feel bad about errors; use them to get better.

Think about what went wrong. Did you heat the solder too much? Did you miss a broken wire while checking? Write down your mistakes in a notebook or on your computer. Keeping track helps you see patterns and avoid repeating errors. Over time, you’ll make fewer mistakes.

By learning from mistakes and practicing, you’ll get better at fixing circuit boards. Repairs will feel easier, and you’ll succeed more often.

How Much Does Circuit Board Repair Cost?

Fixing a circuit board is often cheaper than buying a new device. The price depends on how hard the repair is, the parts needed, and if you hire a pro or do it yourself.

Factors That Affect Costs

| Category | Details |

|---|---|

| Type of Damage | Small problems like broken solder joints cost less to fix. Bigger issues, like replacing chips or fixing multilayer boards, need special tools and skills, which cost more. |

| Labor Costs | Hiring a professional means paying for their time and skill. Prices depend on location and technician’s experience, usually costing $50 to $150 per hour. |

| Replacement Parts | Good-quality parts can be pricey, e.g., special chips or capacitors might cost $5 to $50 each. Cheaper parts save money now but may break sooner. |

| DIY vs. Professional Help | DIY costs are limited to tools and supplies, with a basic repair kit costing about $30 to $100. Professionals charge more but include tests and warranties, adding value. |

Why Circuit Board Repairs Matter

Fixing circuit boards saves money and helps the environment. The market for circuit board holders was worth $4.5 billion in 2024 and could grow to $7.2 billion by 2033. This shows how important repairs are for cutting waste and supporting the electronics industry, which grew about 5.1% yearly from 2018 to 2023.

Repair vs. Replacement Costs

Repairing a circuit board usually costs $50 to $300. Replacing a whole device, especially expensive ones, can cost hundreds or thousands of dollars. Fixing your board saves money and keeps your device working longer.

Tip: Compare repair costs to replacement costs. If fixing it costs less than half of buying new, it’s worth repairing.

Knowing these costs helps you decide the best option. Whether you fix it yourself or hire a pro, repairs save money and reduce waste.

How to Avoid PCB Failures?

Stopping PCB failures needs careful planning and smart actions. By using the right methods, you can make your circuit board last longer and work better.

Pick Good-Quality Parts

Always use good-quality parts for your circuit board. Cheap parts might save money but break faster. Reliable parts lower the chance of problems and improve performance. Trusted brands and certified parts are worth the extra cost.

Test Regularly

Testing often helps find problems early. Use tools like multimeters to check voltage and resistance. Regular tests make sure your circuit board works well. They also stop small issues from becoming big failures.

Add Real-Time Alerts

Real-time alerts warn you about problems right away. These systems check your circuit board for overheating, short circuits, or other issues. Early warnings let you fix problems before they cause serious damage.

Use Smart Fixes for Better Performance

Smart fixes can make your circuit board more dependable. Try these ideas:

- Plug and Play Parts: These are easy to replace without hard repairs.

- Redundancy: Adding extra parts keeps the board working if one fails.

- Jumpers: These allow quick changes to fit different needs.

Study Failures to Learn

Learning why failures happen helps you stop them. Follow these steps:

- Look at when and how failures happen without guessing the cause.

- Check the board closely to find the exact problem.

- Use a Weibull curve to predict when failures might occur.

This method helps you spot patterns and improve your board’s design or care.

Use Data for Tough Problems

For hard issues, data-based methods can help. Tools like regression analysis show how things are connected. Simple programs like Excel can handle this. Simulations are also great for fixing heat or stress problems. These methods help you predict and avoid future issues.

By using these tips, you can prevent common PCB failures and keep your devices working well.

Knowing what damages circuit boards and how to fix them helps your devices last longer. Use the right tools, like a low-heat soldering iron, to avoid overheating. This keeps the board safe from harm. Always follow safety steps, such as wearing gloves and goggles. Work in a space with fresh air to stay safe. Be gentle with tools like desoldering pumps to avoid breaking small parts.

Practice often to get better at repairs. Start with easy fixes before trying harder ones. Each repair makes you more skilled and confident. With care and patience, you can become great at fixing circuit boards and keep your electronics working longer.

FAQs on Circuit Board Repair

Q1. What often causes circuit boards to fail?

Too much heat is the main reason. Heat weakens solder and harms parts. Make sure devices have good airflow. Use fans or heat sinks to keep them cool.

Q2. Can you fix a circuit board without fancy tools?

Yes, simple problems can be fixed with basic tools. Use a soldering iron, multimeter, and rubbing alcohol. For harder repairs, special tools like a hot air station may be needed.

Q3. How do you find broken parts on a circuit board?

Test with a multimeter to check voltage or resistance. Look for burns, cracks, or faded spots. A magnifying glass helps you see small problems.

Q4. Is it safe to repair circuit boards at home?

Yes, if you follow safety rules. Unplug the device, wear goggles, and use an anti-static strap. Work in a clean area with fresh air to stay safe.

Q5. How long does fixing a circuit board take?

It depends on the problem. Easy fixes, like changing a capacitor, take 15–30 minutes. Harder repairs, like multilayer boards, might take hours.

Q6. What if your circuit board repair doesn’t work?

Check your work again. Look at solder joints and connections. Test the board with a multimeter. If it still doesn’t work, ask a professional for help.

Q7. How do you learn how to repair electronics without a degree?

You can learn to repair electronics by taking online courses, watching tutorial videos, practicing with repair kits, and gaining hands-on experience through small repairs.

Q8. What tools are necessary for printed circuit board repair?

Essential tools include a soldering iron, desoldering pump, multimeter, soldering wire, PCB repair kit, and conductive ink for trace repairs.

Q9. How much does a circuit board repair service cost?

PCB repair costs range from $50 to $500 depending on the complexity and severity of the damage.

Q10. What Does PCB Repair and Remanufacturing Consist Of?

When PCB repair isn’t enough, remanufacturing may be necessary. This involves a more in-depth process, including

- Component Replacement: Complete removal and replacement of damaged components, such as BGA rework or IC replacement.

- Rebuilding Traces: For extensive trace damage, rework services may involve rebuilding the damaged sections with conductive traces or new layers.

- Upgrading Components: Sometimes, PCB repair involves upgrading components to improve the circuit’s performance or meet modern standards.

- Layer Reconfiguration: In cases of multi-layer PCBs, reconfiguring or repurposing the board might be necessary to restore its full functionality.

Q11. What Electronic Components and Parts are Necessary for PCB Repairs?

To successfully perform circuit board repairs, you’ll need the right tools and components, including

- Soldering Iron: For soldering and desoldering components.

- Desoldering Pump: To remove solder from connections when replacing components.

- Multimeter: For diagnosing continuity and voltage issues.

- Soldering Wire: Typically, lead-free solder is used to replace components.

- PCB Repair Kit: Includes tools for trace repair, soldering, and cleaning the board.

- Flux: Helps solder flow smoothly and prevents oxidation.

- Conductive Ink: For repairing damaged circuit traces.

- PCB Cleaning Solution: To clean the board after repair work.

Conclusion

Circuit board repair is an essential skill for maintaining and fixing electronic devices. Whether you are dealing with burnt PCBs, damaged traces, or failed components, understanding the repair process and knowing the tools and parts needed can save you time and money.

For those new to PCB repairs, consider starting with simple projects, and be sure to invest in high-quality tools and a PCB repair kit. If you are unsure about the repair process or dealing with complex issues like BGA rework, don’t hesitate to consult a circuit board repair service.

Visit GES PCB for more information on PCB repair, professional services, and the tools you need to get started.